Plantain chips have carved a significant niche in the global snack market as a healthier and culturally rich alternative to traditional potato chips. Behind this growing popularity are state-of-the-art plantain chips making plants, which are revolutionizing snack production, especially in tropical regions where plantains thrive. These plants serve as hubs of innovation, economic development, and sustainable food processing. This article explores their pivotal role, production process, and market trends while highlighting why investing in plantain chip manufacturing is a game-changer.

The Global Rise of Plantain Chips

As consumers worldwide shift towards healthier snack options, the global plantain chip market has experienced remarkable growth. In 2024, the market size reached USD 644.24 million and is projected to grow at a CAGR of 5.42%, reaching USD 982.52 million by 2033. This growth is fueled by increasing health consciousness, plant-based diets, and the demand for ethnic and exotic snacks.

Plantain chips, rich in vitamins, minerals, and dietary fiber, align with current dietary trends such as gluten-free and low-fat diets. Moreover, their versatility in flavors—ranging from sweetened to spicy varieties—makes them appealing to diverse consumer preferences.

Discover advanced plantain chip-making machines here.

The Role of Plantain Chips Making Plants

1. Supporting Local Economies

Plantain chips making plants contribute to the economic development of tropical regions by:

- Utilizing locally grown plantains, reducing reliance on imports.

- Providing employment opportunities in farming, processing, and distribution.

- Encouraging entrepreneurship through small and medium-scale setups.

2. Promoting Sustainable Snack Production

Plantains are a climate-resilient crop, thriving in challenging environments. These plants adopt energy-efficient machinery and eco-friendly practices, ensuring minimal waste and reduced environmental impact.

Learn about sustainable food processing machines.

3. Addressing Health-Conscious Consumer Needs

Modern plantain chip plants are equipped with advanced technologies, such as:

- Baking Equipment for low-fat chips.

- Flavoring Machines for diverse taste profiles.

- Frying Machines with precise temperature control to reduce oil absorption.

Explore flavoring and frying machines for your setup.

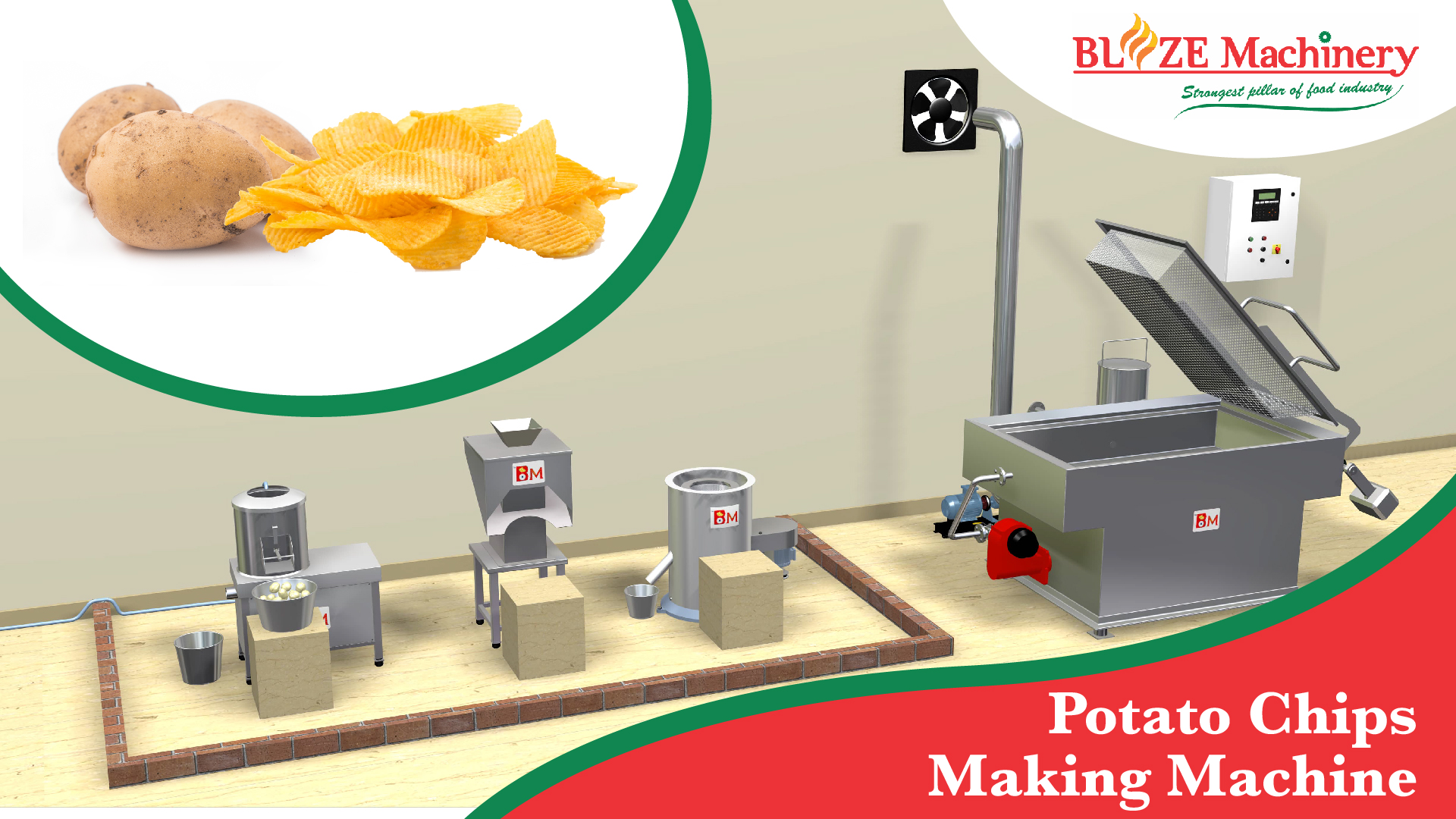

How Plantain Chips Are Made: Step-by-Step Process

1. Sourcing and Selection

High-quality plantains are sourced, ensuring optimal ripeness and nutrient content.

Check out vegetable cutting and slicing machines.

2. Washing and Peeling

Plantains are thoroughly cleaned and peeled using specialized peeling machines.

Discover efficient peeling solutions here.

3. Slicing

Uniform slicing ensures even cooking and texture. Precision slicing machines are critical at this stage.

4. Frying or Baking

- Frying: Plantain slices are cooked in hot oil to achieve a crispy texture.

- Baking: An alternative method for health-conscious consumers, baking reduces fat content while retaining the crunch.

Explore frying and baking machines.

5. Flavoring

Seasoning drums coat the chips with flavors like spicy, sweet, or tangy.

6. Packaging

Modern packaging systems ensure extended shelf life and maintain freshness. Eco-friendly options are becoming increasingly popular.

Learn about innovative packaging applications.

Market Opportunities and Trends

Health-Conscious Consumers

The global rise in demand for snacks perceived as healthy presents immense opportunities for plantain chips.

Product Innovation

Flavored, organic, and baked plantain chips cater to evolving consumer preferences. Innovations in packaging, such as resealable and single-serve options, further drive sales.

Ethnic and Exotic Appeal

With roots in Africa, Latin America, and the Caribbean, plantain chips attract consumers seeking unique cultural experiences.

Challenges in Plantain Chip Production

1. Price Fluctuations

Plantains are seasonal, leading to price volatility. Investing in efficient supply chains can mitigate this challenge.

2. Quality Control

Maintaining consistent taste and texture is crucial for market acceptance. Advanced quality control systems help address this.

3. Competition

Competing with well-established snacks like potato chips requires effective marketing and innovation.

Why Invest in a Plantain Chips Making Plant?

1. High ROI Potential

With growing demand and relatively low setup costs, plantain chip plants offer attractive returns on investment.

2. Scalable Business Model

Plants can start small and expand as demand grows, catering to both local and international markets.

3. Support from Modern Machinery

Advanced machinery, such as automatic slicing, frying, and flavoring equipment, simplifies production and ensures consistent quality.

Explore chips-making plants tailored for your needs.

Plantain Chips vs. Other Snacks

| Feature | Plantain Chips | Potato Chips |

| Fat Content | Lower (baked option available) | High |

| Nutrient Density | High in fiber and vitamins | Low |

| Gluten-Free | Yes | No |

| Versatility in Flavors | Wide range, including exotic | Limited |

| Cultural Significance | High in tropical regions | Minimal |

Learn more about healthy snack production.

Your Partner in Plantain Chip Production

At Blaze Machinery, we specialize in providing end-to-end solutions for setting up plantain chips making plants. From sourcing the best machinery to offering expert guidance, we ensure your plant meets market demands efficiently.

- Semi-Automatic Plants: Ideal for startups with limited budgets.

- Fully Automatic Plants: Designed for large-scale production with minimal labor requirements.

Recent Comments