Banana chips have gained global recognition as a healthy, flavorful snack, making their production an attractive venture for manufacturers. What sets banana chips plants apart is their ability to enable cost-efficient operations while maintaining high-quality output. With innovative machinery, semi-automatic systems, and versatile functionality, these plants are designed to optimize production at minimal cost. Let’s explore why banana chips plants are ideal for low-cost production, covering everything from their compact design to energy-efficient systems.

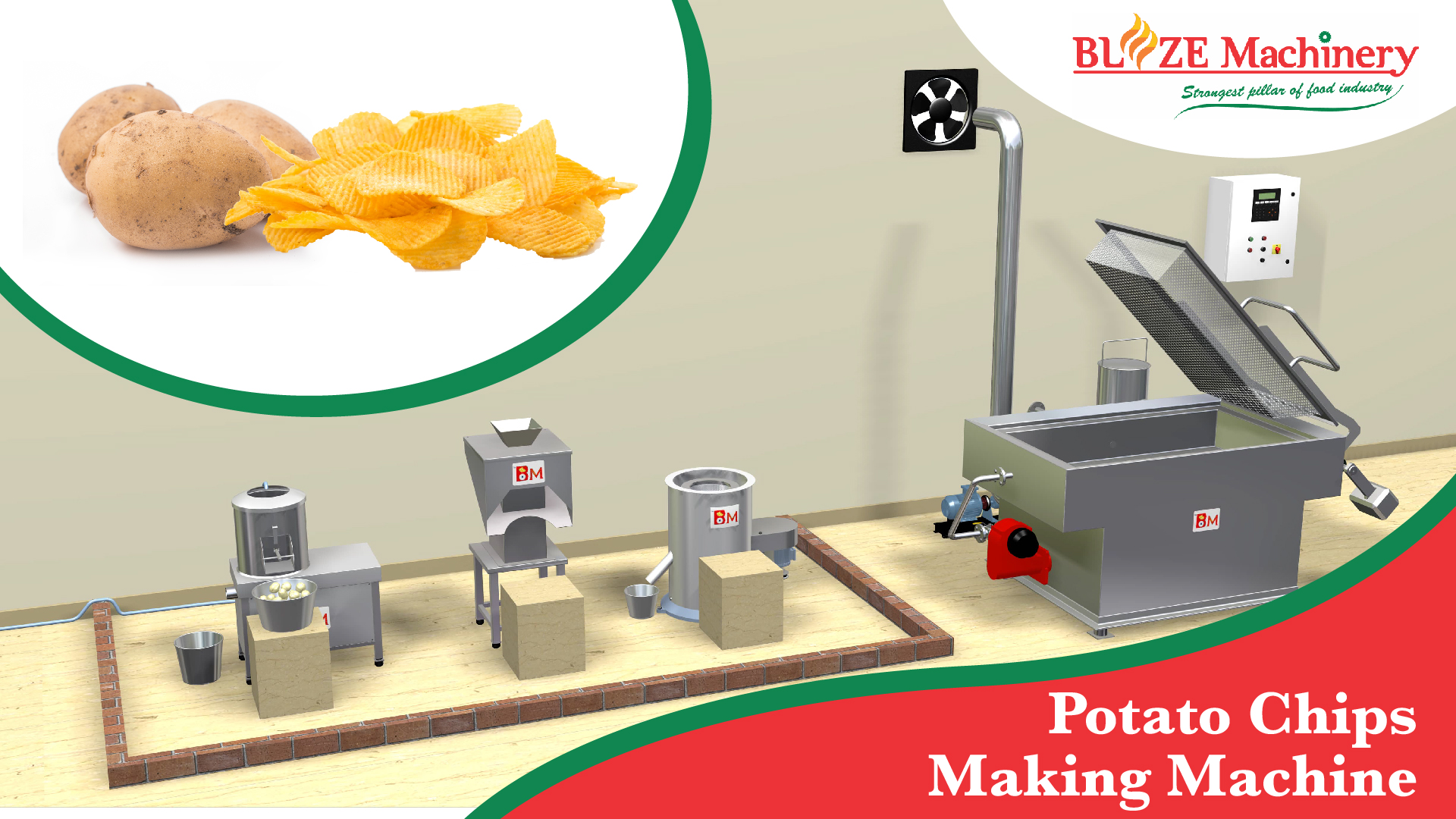

Compact Design for Space Optimization

One of the standout features of banana chips plants is their small footprint. These plants are compact enough to fit into spaces as small as 80 to 100 square meters. This makes them highly suitable for small and medium-scale manufacturers, especially in urban or space-constrained areas. By utilizing minimal space, these plants reduce overhead costs associated with large-scale facilities.

Explore space-saving banana chips plants.

Semi-Automatic Systems for Cost Efficiency

Semi-automatic banana chips production lines strike a balance between automation and manual labor. Workers handle tasks like feeding products into machines, while automated systems manage processes such as slicing, frying, and seasoning. This setup reduces labor costs while maintaining flexibility in production.

Key Equipment in Semi-Automatic Lines:

- Banana Slicing Machine : Precisely slices bananas into uniform chips.

- Frying Machine : Advanced oil-water mixing technology ensures consistent frying.

- De-oiling Machine: Removes excess oil, enhancing taste and reducing fat content.

- Seasoning Machine : Evenly coats chips with desired flavors.

- Vertical Packing Machine : Automates packaging for extended shelf life.

Each piece of equipment is designed for durability, efficiency, and ease of operation.

Learn more about semi-automatic production lines.

Use of Food-Grade Materials

Banana chips plants are constructed using stainless steel and other food-grade materials. This ensures compliance with food safety standards while enhancing durability and corrosion resistance. The high-quality build minimizes maintenance costs, making these plants a cost-effective investment.

Discover durable food processing machines.

Multi-Functional Machinery for Versatility

Many banana chips plants come equipped with multi-functional machinery that can also process other fruits and vegetables like sweet potatoes, plantains, and apples. This versatility allows manufacturers to diversify their product lines without requiring additional equipment.

Explore multi-functional equipment for your plant.

User-Friendly Interfaces for Easy Operation

Banana chips machines are designed with digital control panels and user-friendly interfaces. This minimizes the need for extensive training and ensures that the production process is smooth and efficient. Operators can easily adjust settings for slicing thickness, frying temperature, and seasoning levels, ensuring consistent quality.

Energy-Efficient Features for Cost Savings

Energy efficiency is a critical factor in reducing operational costs. Banana chips plants incorporate advanced technologies like:

- Electric or Gas Heating: Dual heating options optimize energy use.

- Oil-Water Mixing Technology: Reduces oil consumption during frying.

- Centrifugal De-oiling: Removes excess oil efficiently, lowering energy requirements for frying.

By integrating these energy-saving systems, manufacturers can significantly reduce utility expenses while maintaining production quality.

Find energy-efficient frying machines here.

Detailed Workflow of Banana Chips Production

The semi-automatic banana chips production line follows a streamlined process:

- Peeling: Green bananas are peeled either manually or using a banana peeling machine.

- Slicing: Peeled bananas are sliced into uniform chips using a precision slicing machine.

- Frying: Banana slices are fried at optimal temperatures for 4-5 minutes.

- De-oiling: Excess oil is removed to ensure crispy and flavorful chips.

- Seasoning: Chips are flavored with sweet, salty, or spicy seasonings.

- Packaging: Chips are packed into nitrogen-filled bags for extended freshness.

Learn more about each step in banana chips production.

Affordable Production Costs

Factors Contributing to Low Costs:

- Raw Materials: Green bananas are affordable and widely available.

- Automation: Reduces dependency on manual labor.

- Energy Efficiency: Lowers utility bills.

- Compact Size: Minimizes facility costs.

These features make banana chips plants an excellent choice for startups and small-scale manufacturers looking to enter the snack industry with minimal investment.

Why Invest in Banana Chips Plants?

- High ROI Potential: Low initial costs combined with high demand for banana chips ensure attractive returns.

- Scalability: Start small and expand as demand grows.

- Sustainability: Energy-efficient systems reduce environmental impact.

- Global Market Demand: Banana chips are popular in markets across Asia, Africa, and beyond.

Contact us to start your banana chips production.

Banana chips plants offer an unbeatable combination of affordability, efficiency, and scalability. By investing in the right equipment and processes, manufacturers can tap into the growing demand for banana chips while keeping production costs low. Ready to start your journey?

Recent Comments