Cassava chips making plants are transforming the global snack industry by offering a versatile, sustainable, and cost-effective alternative to traditional potato chips. As cassava is a widely cultivated staple crop in tropical regions, its use in snack production supports local economies, promotes food security, and diversifies snack options. Let’s explore the essential role of cassava chips making plants in revolutionizing snack production worldwide.

Why Cassava Chips Are a Game-Changer in the Snack Industry

Cassava chips are gaining popularity as a healthier and more sustainable snack option. Here’s why they stand out:

- Expanding Snack Variety: Cassava chips introduce a unique taste and texture, offering an alternative to potato chips and meeting the demand for innovative snack options.

- Nutritional Benefits: Cassava chips are rich in carbohydrates and provide essential vitamins and minerals, such as vitamin C and potassium, making them a nutritious snack choice.

- Climate Resilience: Cassava thrives in challenging climates, including drought-prone regions, making it a reliable crop for consistent snack production.

- Economic Impact: Establishing cassava chips making plants creates employment opportunities, boosts local economies, and adds value to cassava farming.

- Sustainability: Using a locally grown crop reduces reliance on imported ingredients and minimizes the carbon footprint of snack production.

Explore cassava chips making plants and equipment here.

How Cassava Chips Making Plants Contribute to Global Snack Production

Cassava chips manufacturing plants play a crucial role in producing high-quality snacks while supporting sustainability and economic development:

- Utilizing Local Resources: Cassava, a staple in many tropical regions, serves as a readily available raw material, reducing transportation costs and promoting self-sufficiency. Discover peeling machines for cassava processing.

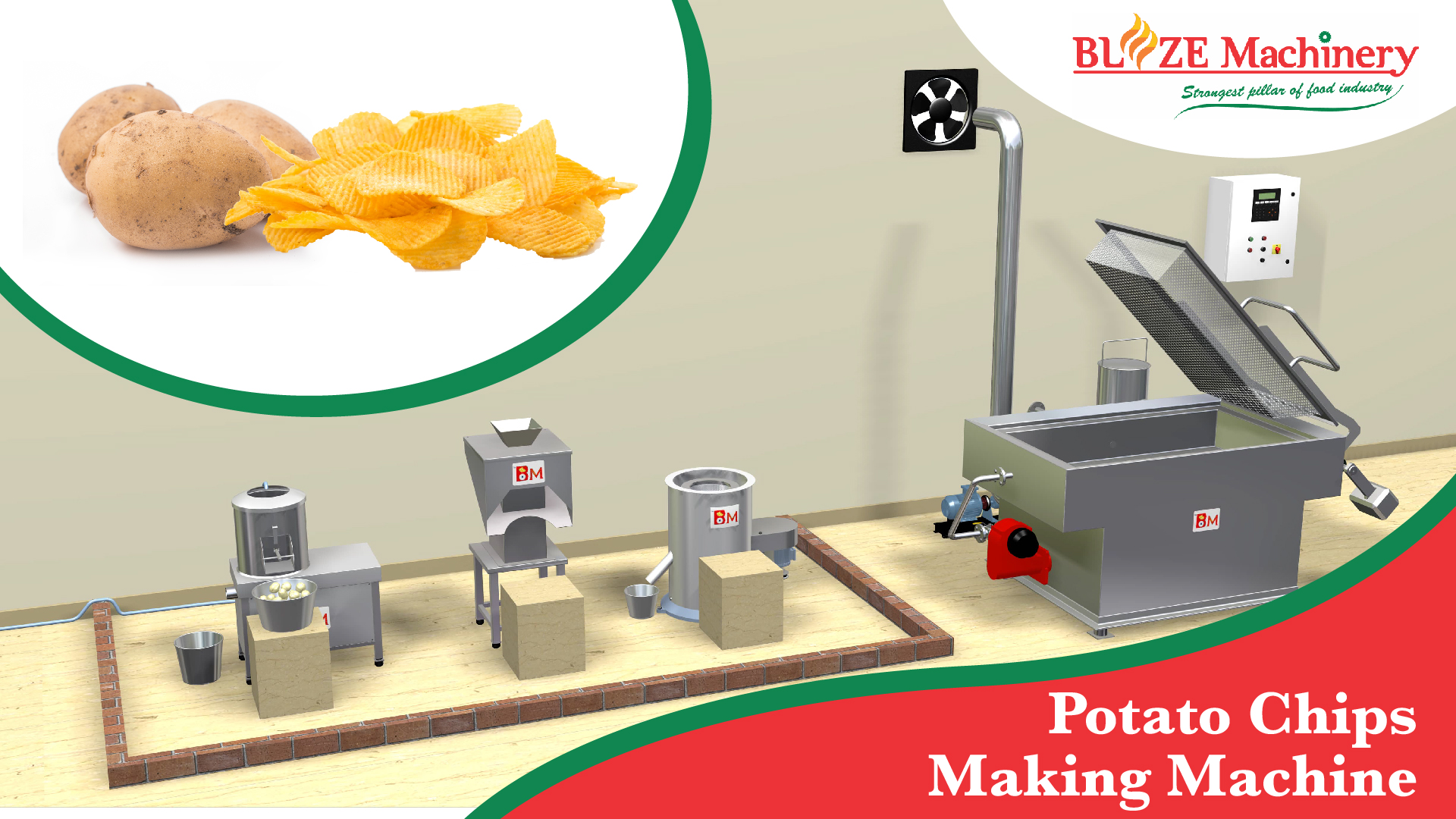

- Advanced Processing Techniques: Modern plants use efficient machinery for peeling, slicing, frying, and drying cassava to produce crispy and flavorful chips. Learn about food processing machines here.

- Customizable Production Lines: Cassava chip plants can scale operations based on market demand, catering to both small-scale and large-scale production needs.

- Health-Focused Production: By limiting additives and using minimal oil, cassava chips are positioned as a healthier snack option. Check out frying machines for cassava chips.

- Eco-Friendly Practices: Many plants adopt sustainable production and packaging methods, aligning with global environmental goals.

Watch videos of cassava chips production lines in action.

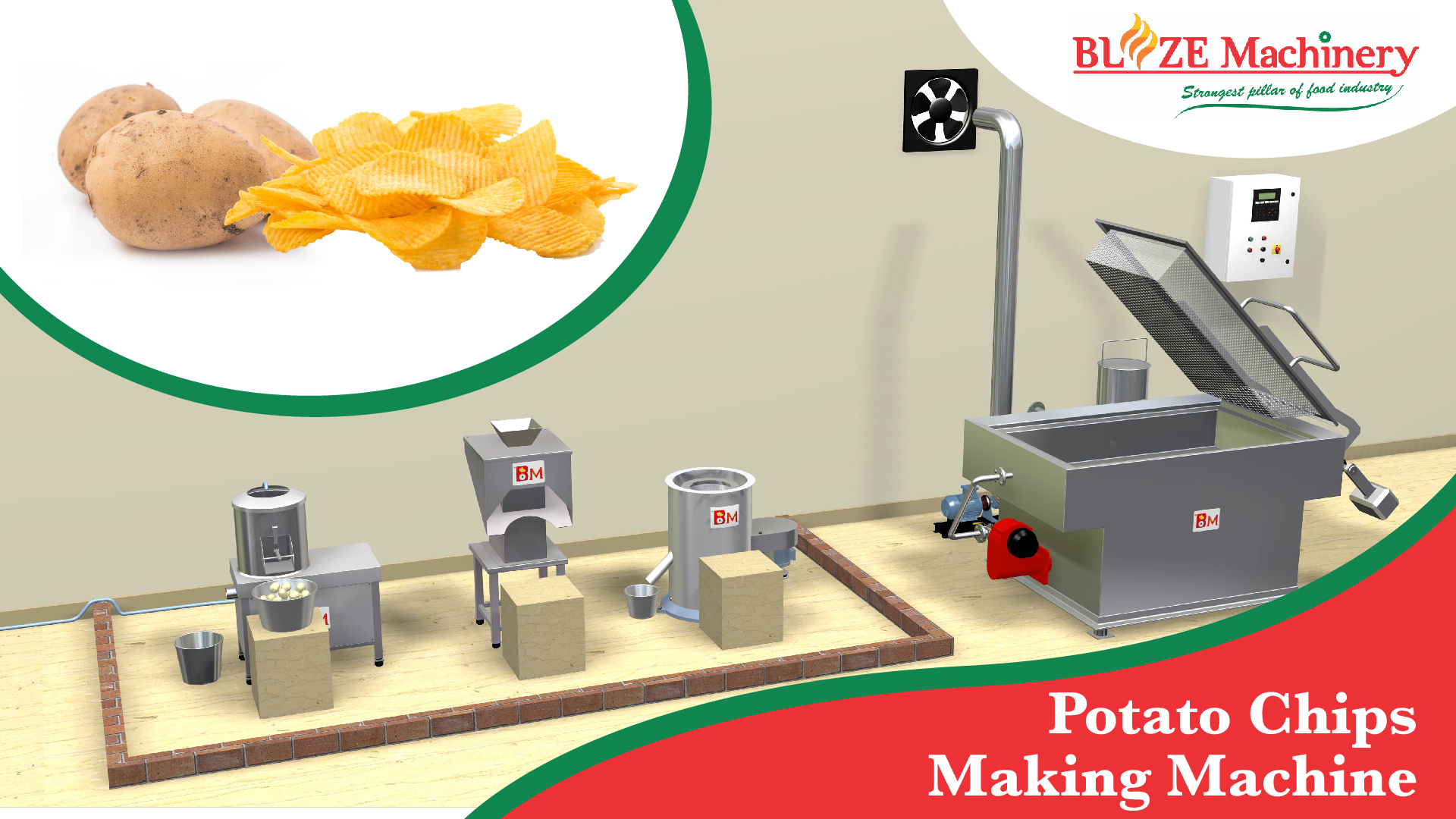

Cassava Chips Production Process

The production of cassava chips involves several key steps to ensure quality and efficiency:

- Cassava Selection: High-quality cassava roots are selected and cleaned.

- Peeling: The roots are peeled using specialized peeling machines to remove the outer layer. Explore our range of peeling machines.

- Slicing: Uniform slices are achieved using advanced vegetable cutting and slicing machines. View slicing machines here.

- Soaking: The slices are soaked in brine to enhance flavor and improve texture.

- Frying or Drying: The chips are fried or dried, depending on the desired product type, using efficient drying and frying machines. Discover food drying machines.

- Flavoring: Chips are seasoned with natural flavors or spices using flavoring machines. Learn more about flavoring machines.

- Packaging: The final product is packed in eco-friendly packaging to maintain freshness. Explore packaging solutions here.

Key Benefits of Cassava Chips

| Feature | Cassava Chips | Traditional Snacks |

| Fat Content | Low | High |

| Sustainability | High | Moderate |

| Nutritional Value | Rich in carbs, vitamins | Low |

| Raw Material Availability | Locally grown | Often imported |

| Economic Impact | Supports local farmers | Minimal local benefit |

Cassava chips clearly outperform traditional snacks in sustainability and economic impact. Find the best machinery for cassava chips production.

Challenges in Cassava Chips Production

While cassava chips have immense potential, manufacturers must address certain challenges:

- Cyanide Content: Raw cassava contains cyanogenic compounds that require proper processing to ensure safety.

- Quality Control: Maintaining consistent flavor and texture is essential for market success.

- Consumer Awareness: Educating consumers about the benefits of cassava chips can drive demand.

Global Market Trends for Cassava Chips

The cassava chips market is witnessing rapid growth due to increasing health consciousness and demand for sustainable snacks. Key trends include:

- Rising Health Awareness: Consumers are opting for low-fat, gluten-free snacks, making cassava chips a popular choice.

- Expansion of Retail Channels: Supermarkets, convenience stores, and online platforms ensure easy accessibility. Shop cassava chips processing machines online.

- Sustainability Focus: Manufacturers are adopting eco-friendly production and packaging practices.

Investing in a Cassava Chips Manufacturing Plant

Setting up a cassava chips manufacturing plant offers significant opportunities for entrepreneurs:

- High Demand: The global market for healthier snacks is expanding rapidly.

- Cost-Effective Setup: With affordable machinery, cassava chips plants provide a viable business opportunity. Get started with cost-effective machinery here.

- Economic Development: Supporting local farming communities and creating jobs boosts regional economies.

- Scalability: Plants can scale operations to meet growing market demands.

Contact us to start your cassava chips plant.

Your Partner in Cassava Chips Manufacturing

At Blaze Machinery, we provide end-to-end solutions for cassava chips manufacturing. From advanced machinery to expert guidance, we help you establish a successful snack production business. Our customizable production lines ensure efficiency and scalability for businesses of all sizes.

- Semi-Automatic Plants: Ideal for small-scale production. Learn more about semi-automatic options.

- Fully Automatic Plants: Perfect for large-scale operations. Explore fully automatic setups.

Conclusion

Cassava chips making plants are playing a transformative role in global snack production. By utilizing locally grown cassava, these plants not only create delicious and nutritious snacks but also contribute to economic growth and sustainability. Whether you’re an entrepreneur or an established manufacturer, investing in cassava chips production is a step toward a healthier, more sustainable future.

Recent Comments