The potato chips industry is evolving rapidly, with manufacturers increasingly prioritizing energy efficiency to meet sustainability goals, reduce production costs, and enhance profitability. As energy consumption remains one of the major operational costs in chip production, implementing energy-efficient solutions is no longer an option but a necessity. From advanced frying systems to innovative heat recovery technologies, this article delves into how potato chips making plants are revolutionizing their operations to optimize energy usage and minimize environmental impact.

Why Energy Efficiency Matters in Potato Chips Production

Energy consumption in potato chips manufacturing is predominantly driven by frying processes, which account for more than 90% of total energy usage. With growing concerns about greenhouse gas emissions, energy costs, and resource sustainability, adopting energy-efficient practices has become crucial. Additionally, governments worldwide are introducing regulations and incentives to encourage energy-efficient manufacturing, making it an opportune time for chip manufacturers to invest in sustainable solutions.

Key benefits of energy-efficient practices include:

- Reduced operational costs.

- Lower carbon footprint.

- Enhanced product quality and consistency.

- Improved competitiveness in the global market.

Explore energy-efficient potato chips plants.

Top Energy-Saving Strategies in Potato Chips Making Plants

- Heat Recovery Systems

Heat recovery systems capture and reuse energy from high-temperature processes, such as frying and baking. For instance, heat generated by ovens or fryers can be recycled to preheat water or power steam turbines, significantly reducing energy waste.A North American chip manufacturer saved $27,810 annually and reduced CO2 emissions by 205 metric tons through heat recovery boilers that convert exhaust gases into reusable steam. By investing in such systems, manufacturers can achieve quick returns on investment while improving sustainability.

Discover advanced frying machines with heat recovery features.

- Insulation and Temperature Control

Insulating equipment and pipelines prevents heat loss, ensuring optimal temperature control during frying and baking processes. Efficient insulation reduces energy consumption, particularly in high-temperature environments where potato chips machines operate.Practical tips include:

- Using insulated containers for transporting raw materials.

- Installing double-paned windows in production areas.

- Monitoring and maintaining consistent frying temperatures to avoid energy wastage.

- Automation and Smart Technology

Automation systems, such as motion sensors and digital monitoring, play a vital role in optimizing energy usage. Fully automated potato chips production lines enhance precision, reduce human errors, and improve overall energy efficiency.

- Motion Sensors: Detect idle machinery and automatically shut them off to prevent unnecessary power consumption.

- Digital Monitoring Systems: Provide real-time data on energy usage, enabling manufacturers to identify inefficiencies and implement corrective measures.

Learn more about fully automated potato chips production lines.

- Upgraded Frying Equipment

Modern frying equipment is designed with energy-saving technologies, such as controlled oil temperatures, reduced heat loss, and precise frying times. Investing in high-efficiency fryers can significantly lower energy consumption while maintaining product quality.

Check out energy-efficient frying machines.

- Renewable Energy Integration

Incorporating renewable energy sources, such as solar power or wind turbines, into manufacturing plants is a forward-thinking approach to achieving energy independence. Solar panels can power essential machinery, while wind turbines generate electricity for auxiliary operations, reducing reliance on fossil fuels.

The Role of Modern Technology in Energy Efficiency

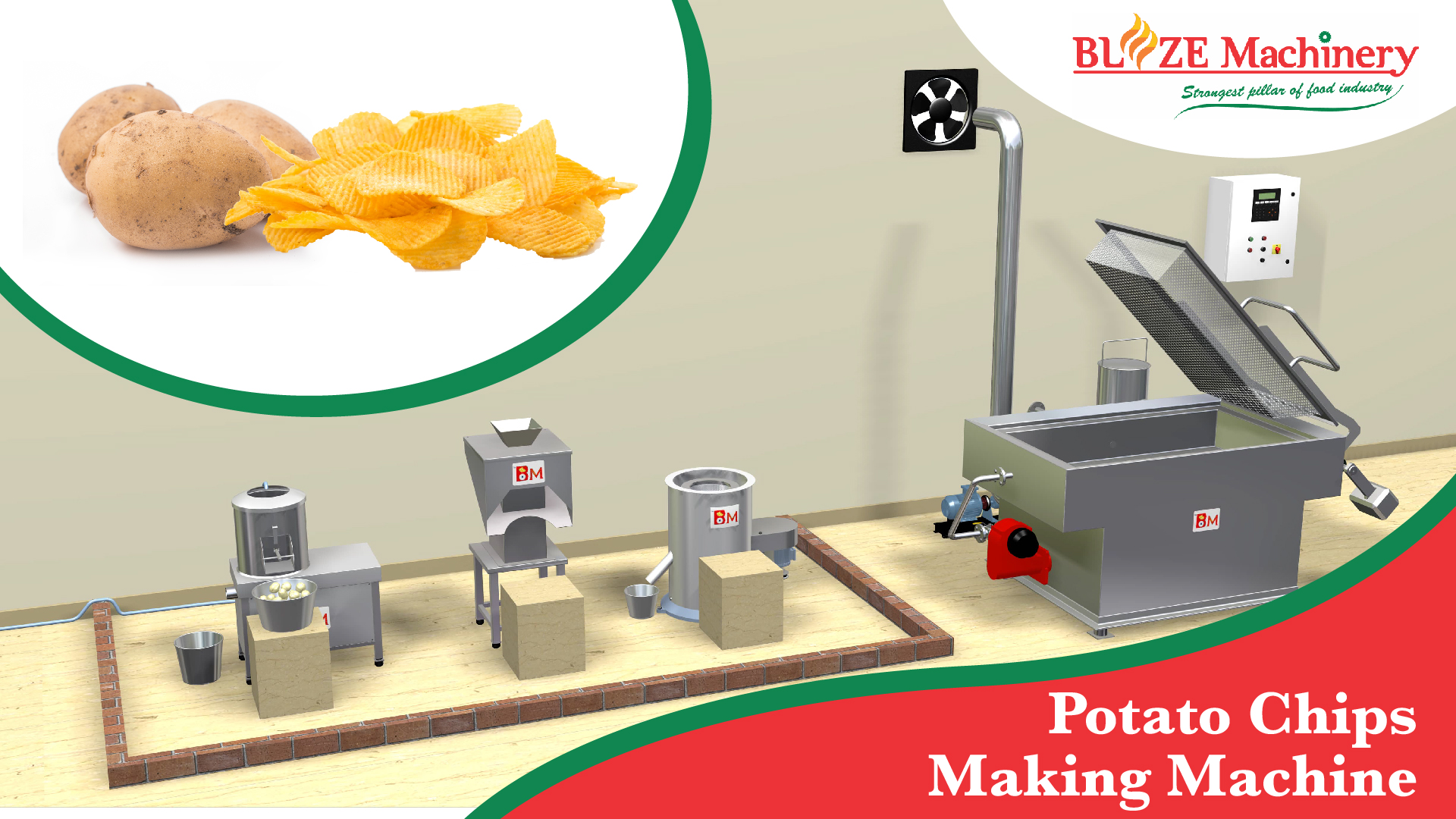

Modern technology is revolutionizing potato chips production by integrating energy-efficient solutions into every stage of the process. Key advancements include:

- Advanced Peeling and Cutting Machines

Automated peeling and slicing machines ensure minimal energy usage while delivering consistent results. Precision equipment reduces material waste, contributing to overall efficiency.

Discover innovative peeling machines.

- High-Efficiency Flavoring Systems

Energy-efficient flavoring machines, such as masala coating systems, ensure uniform seasoning with minimal power usage. These machines cater to diverse consumer preferences while optimizing energy consumption.

Explore flavoring machines for your production line.

- Food Drying and Packaging Innovations

Food drying systems equipped with advanced heat control technology reduce energy usage during the dehydration process. Additionally, eco-friendly packaging solutions, such as biodegradable materials, enhance sustainability.

Learn about food drying machines.

Maximizing ROI with Energy-Efficient Chips Making Plants

Investing in energy-efficient potato chips making plants not only reduces operational costs but also enhances profitability and market appeal. Manufacturers can scale operations without increasing energy costs by:

- Adopting semi-automatic or fully automatic production lines.

- Utilizing heat recovery systems to minimize energy loss.

- Implementing regular maintenance schedules to ensure optimal equipment performance.

Contact us to set up your energy-efficient chips making plant.

FAQs on Energy-Efficient Potato Chips Production

- How can potato chips plants reduce energy consumption?

Potato chips plants can reduce energy consumption by investing in heat recovery systems, insulating equipment, automating processes, and integrating renewable energy sources. - What are the benefits of energy-efficient frying machines?

Energy-efficient frying machines minimize heat loss, reduce oil consumption, and maintain consistent frying temperatures, resulting in lower energy costs and improved product quality. - Is it cost-effective to upgrade to energy-efficient equipment?

Yes, upgrading to energy-efficient equipment offers long-term savings through reduced energy bills, lower maintenance costs, and faster ROI. - Can renewable energy be used in potato chips production?

Absolutely! Solar panels and wind turbines can power production lines and auxiliary systems, reducing reliance on fossil fuels. - What is the environmental impact of energy-efficient chips production?

Energy-efficient production reduces greenhouse gas emissions, minimizes waste, and promotes sustainable manufacturing practices.

By implementing these energy-efficient solutions, potato chips making plants can achieve sustainable growth while meeting the rising demand for high-quality snacks. Blaze Machinery is here to support your journey with state-of-the-art equipment and expert guidance.

Explore our complete range of solutions today!

Recent Comments