The Lucrative World of Chips Making Plants

The chips making industry stands as a flourishing sector within the global food processing market, centered around the production of a universally cherished snack – potato chips. Its growth has been remarkable, owing to the widespread popularity and consistently high demand for this beloved snack.

Why Invest in a Chips Making Plant?

Investing in a chips making plant holds several compelling reasons. Firstly, the demand for potato chips remains steadfast, making it a dependable market with reduced business risk. Moreover, the profitability potential is substantial, especially with efficient operations and the right equipment in place. Additionally, the industry offers ample room for creativity and innovation, allowing plant owners to experiment with flavours, textures, and packaging to cater to diverse tastes and preferences. Beyond profitability, establishing a chip making plant has a positive impact on the local economy by generating employment opportunities at various skill levels, thus contributing to the community’s economic well-being. Furthermore, the chips industry has proven resilient even during economic downturns, as snacks like chips continue to be sought-after indulgences, making it a relatively recession-resistant venture.

Market Trends and Opportunities Chips Making Industry

Current market trends and opportunities in the chips making industry are noteworthy. With an increasing focus on health-conscious consumption, there’s a growing demand for healthier snack options. This has led to the development of baked, low-fat, and alternative ingredient chips, creating a niche market. Additionally, the global appeal of potato chips transcends geographical boundaries, presenting opportunities for expansion into international markets with effective marketing and distribution strategies. Flavour innovation is another critical trend, with consumers showing a penchant for unique and exotic taste experiences. Experimenting with diverse seasonings and flavour profiles can establish a chip brand as distinctive in a competitive market. Moreover, the conscious shift towards sustainable practices in consumer choices extends to snacks, opening avenues for brands that emphasize eco-friendly packaging and responsible ingredient sourcing. Finally, the integration of e-commerce platforms in shopping habits provides an additional channel for sales and brand exposure, making it an opportune avenue for growth in the chips making industry.

Planning Your Chips Making Venture

Embarking on a chip making venture requires meticulous planning to ensure its success. This phase involves crucial steps like conducting comprehensive market research, selecting the optimal location, and addressing legal considerations and permits:

Conducting Market Research: Market research forms the bedrock of any successful business endeavour, and the chips making industry is no exception. This step involves a detailed analysis of consumer preferences, buying behaviours, and emerging trends in the snack industry. It’s essential to identify target demographics, assess competition, and gain insights into potential market niches. Understanding the demand-supply dynamics and market fluctuations will enable you to make informed decisions and tailor your products to meet consumer expectations.

Choosing the Right Location: Selecting the appropriate location for your chips making plant is a critical decision that can significantly impact operational efficiency and market reach. Factors to consider include proximity to reliable potato suppliers, accessibility to distribution channels, and availability of skilled labour. Additionally, a location that complies with zoning regulations and offers logistical advantages can streamline production processes and reduce transportation costs.

Legal Considerations and Permits: Navigating the legal landscape is essential to ensure compliance and avoid potential setbacks. This involves obtaining the necessary permits and licenses for operating a food processing facility. Health and safety regulations, environmental compliance, and adherence to food quality standards are paramount. Engaging legal counsel or consulting with regulatory authorities can help you navigate the intricate web of legal requirements, ensuring that your chip making venture operates within the bounds of the law.

By meticulously planning each aspect of your chip making venture, from thorough market research to selecting the right location and addressing legal considerations, you lay a solid foundation for a successful and sustainable business. This strategic approach sets the stage for the subsequent stages of setting up and operating your chips making plant.

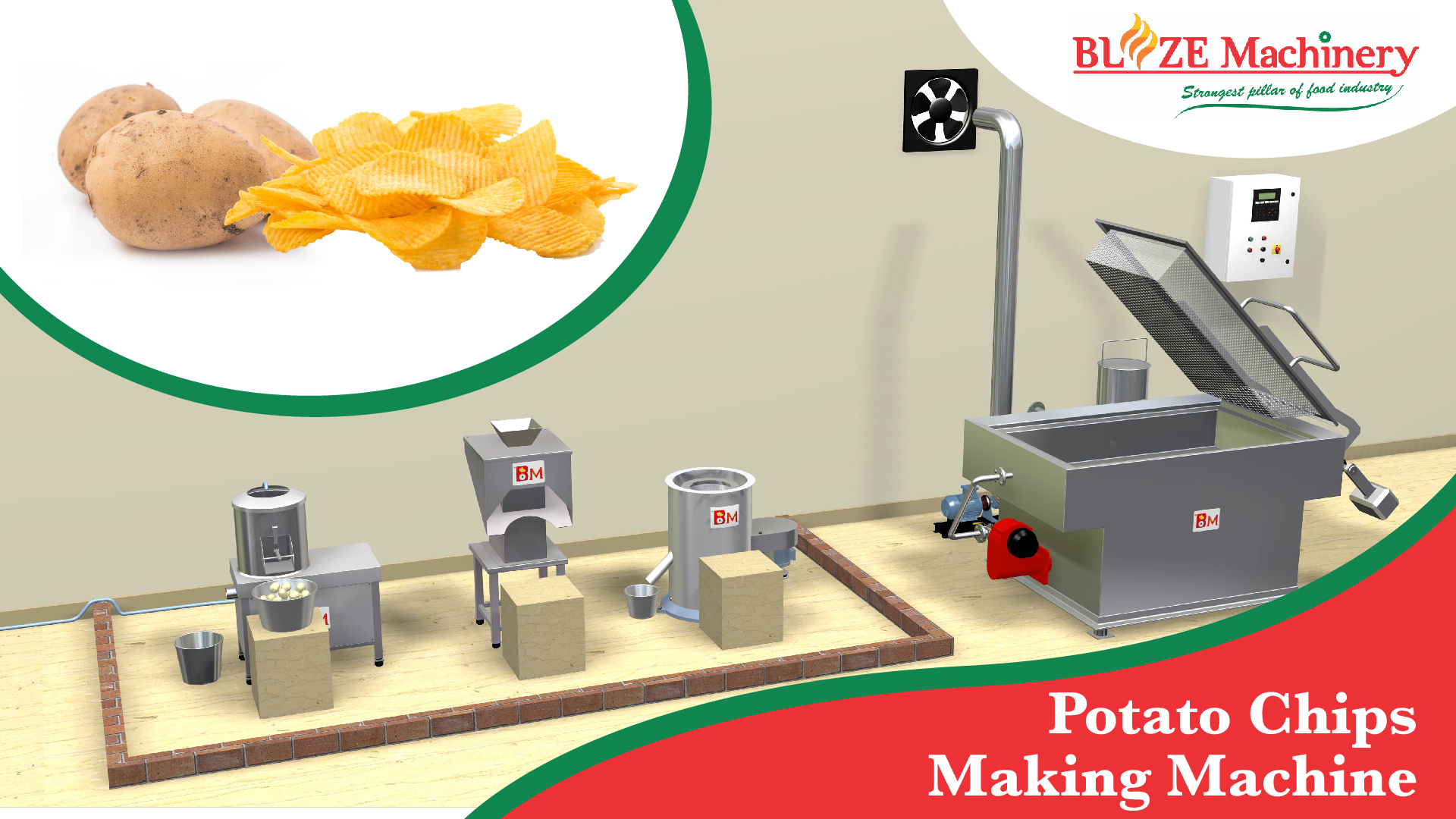

Understanding Chips Manufacturing Process

To excel in the chips making industry, it’s imperative to grasp the intricacies of the manufacturing process. This involves a series of steps, starting with potato selection and preparation, followed by cutting and slicing techniques, and concluding with pre-treatment and seasoning.

Potato Selection and Preparation: The foundation of exceptional chips lies in the quality of the potatoes chosen. Opt for fresh, firm, and high-starch varieties, which yield the desired crispiness and flavour. Thorough cleaning and removal of any blemishes or impurities are crucial. Proper storage in controlled environments ensures the potatoes remain in optimal condition until they’re processed.

Cutting and Slicing Techniques: Achieving the perfect chip thickness is an art. Industrial-grade machines with customizable settings are employed to slice the potatoes uniformly. This process determines the texture and consistency of the final product. From thin and crispy to thicker, heartier chips, the cutting technique plays a pivotal role in meeting consumer preferences.

Pre-Treatment and Seasoning: Before the frying stage, pre-treatment steps are vital for enhancing taste and texture. This may involve rinsing to remove excess starch, blanching to preserve color, or other techniques to achieve specific results. Seasoning, a cornerstone of chip flavour profiles, is carefully applied. This step demands precision to achieve a balanced and consistent taste across each batch.

Mastering the chips manufacturing process requires a combination of technical expertise, quality ingredients, and attention to detail. By honing these three essential stages—potato selection and preparation, cutting and slicing techniques, and pre-treatment and seasoning—you pave the way for producing chips that stand out in taste and texture, satisfying the discerning palates of consumers.

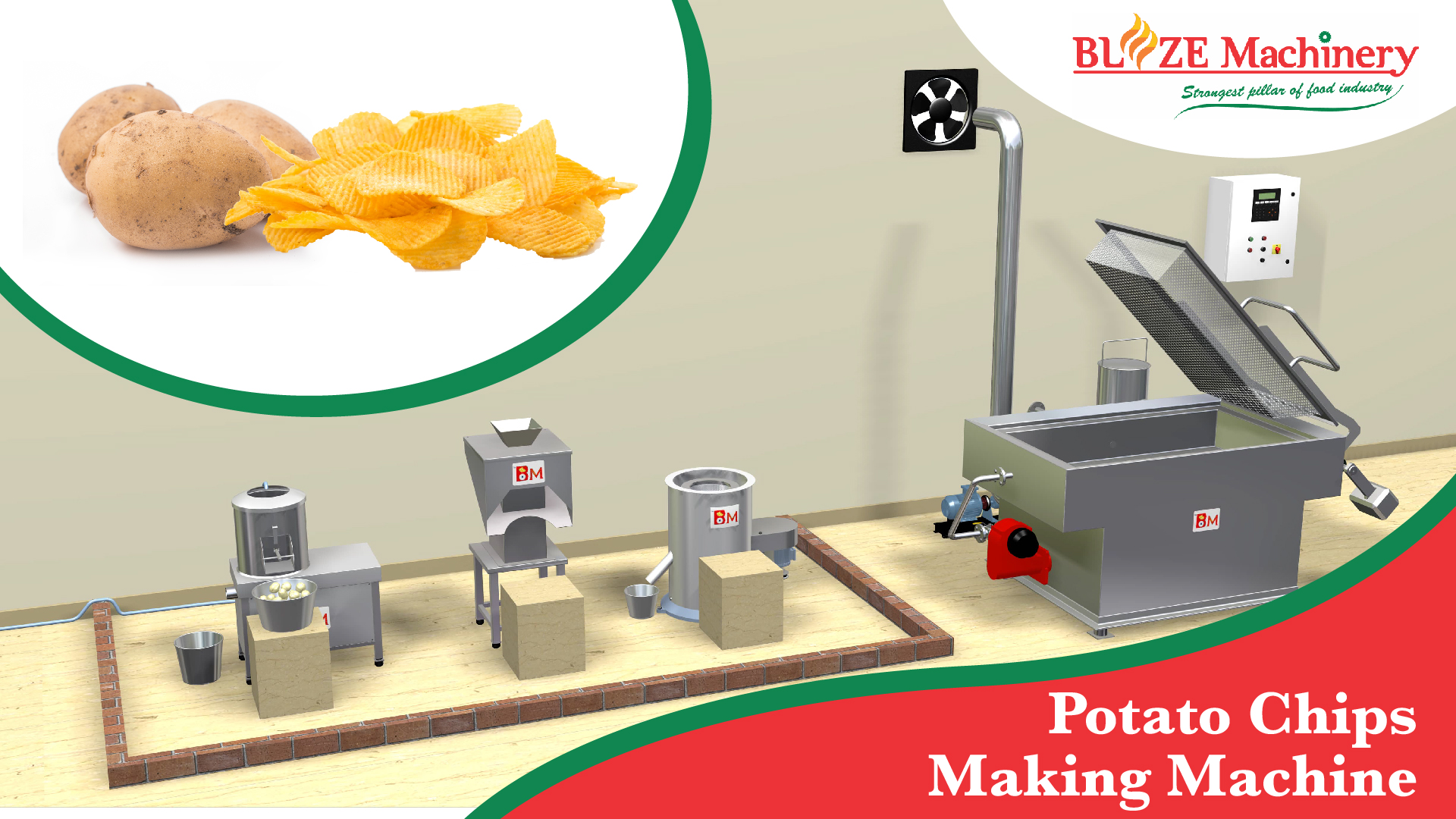

Potato Chips Making Plant: Optimizing Production Efficiency

Optimizing production efficiency in a potato chips making plant is paramount for a successful and profitable operation. This involves implementing strategies and employing technologies to streamline processes, reduce wastage, and enhance overall output. Utilizing state-of-the-art cutting and frying equipment, implementing lean manufacturing principles, and fine-tuning seasoning and packaging processes are key steps. Additionally, regular maintenance schedules, effective workforce management, and embracing sustainable practices all contribute to a more efficient and sustainable potato chips manufacturing venture. By prioritizing efficiency, you not only increase productivity but also position your plant for long-term success in the competitive snacks market.

Building a Profitable Future in Chips Production with Blaze Machinery

Venturing into the chips production industry holds immense potential for entrepreneurs and investors alike. By meticulously planning every aspect of your chip making plant, from market research to legal considerations, you establish a solid foundation for success. Understanding the nuances of the manufacturing process, from potato selection to pre-treatment and seasoning, allows you to create a product that stands out in taste and texture.

For those seeking reliable machinery for their Chips Making Plant, Blaze Machinery emerges as a prominent manufacturer and rapidly evolving company in this field. Our commitment to quality and innovation makes us a valuable partner in realizing your vision for a successful chips production venture. With the right strategies, dedication to quality, and a forward-thinking approach, you’re well-positioned to build a profitable future in the dynamic and ever-popular chips production industry. Contact Us Today!

Recent Comments