Introduction to Sigma Blade Mixer

The sigma mixer is a frequently used mixer for providing heavy-duty viscosity. This Blog demonstrates the operation, architecture, purpose and working competence of the sigma mixer. The different substitution intended for the sigma mixer is considered. The sigma mixer and Dough mixer is one of the most familiar uses of heavy viscosity tools for mixing and kneading. It is a member of the double arm kneader mixer family.

Understanding Sigma Blade Technology

It is vital to support tangential and diagonal movement of the chemical in mixers which manage acidic products. The sigma blade’s geometry and design is intended to draw, shear, coarse, knead, and fold the glutinous mass of material by the blade operate beside the mixer trough’s sides. The sum this happens to depends on the blade hack-peripheral or intersection, and the blade replacement rate ratio. The blade’s twist angle can be adjusted to match the suitable shear.

Exploring the Tangential and Overlapping Blade Action

In the horizon the blades plan to flap in the trough assembly imaginatively the front blade generally moves faster than the back blade more frequently than not in the 3:2 ratios. Peripheral blades are generally used for greater viscosity materials such as rubber paste, glue, flush colour, dye, and pigment.

In the overlap strategy the blades reach beyond the container’s burden. It is essential that the skilled position of the both blades is not affected due to the overlying exploit, and as a result both the blades flap at a similar speed. Using the overlap blade motion, materials which flow easily or travel stealthily down into the blade are varied.

Efficient Operation of the Sigma Blade Mixer

In procedure, material is loaded at the top of the container from side to side distinctively 40% to 65% of the entire volumetric capacity of the mixer. The blade standby is characterized by a severe duty drive system consisting of an engine, gearbox, coupling and gears. The sigma blender’s tip speed is usually insufficient, up to 60 meters per minute. Mixing may be permissible at average temperature, or under unhealthy conditions of heat. To maintain the needed temperature situation inside the blender, the mixer trough can provide jackets for the transmission of hot or cold media.

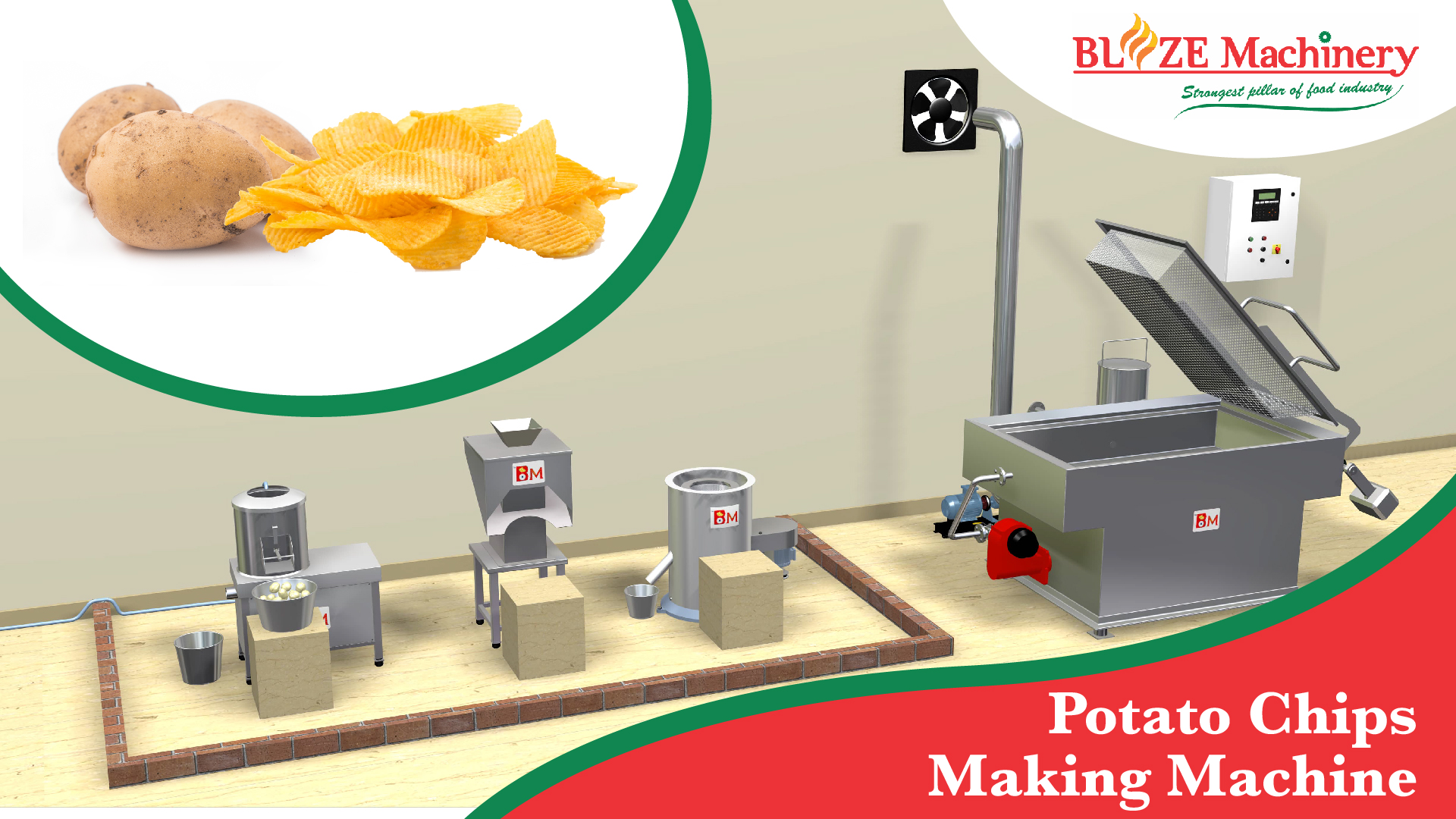

Where to Buy Sigma Blade Mixer

Blaze Machinery is a prominent manufacturer, supplier & exporter in the business of Sigma mixer production. Located in Mumbai, we have more than 20 years of expertise in this field of manufacturing a wide range of batch & continuous food processing machines. If you want to buy finest quality sigma mixer then Contact us via phone or email or visit our website https://blazemac.com/

Recent Comments